Lamp Harps for Sale - Sizes available to fit any lamp!

Lamp Shade Harps are made from brass or silver. Their 2 legs mount below the lamp socket “saddle” and holds up your lamp shade. Most of our lamp harps include the saddle, but you can generally use the one already installed on your lamp.

With several sizes and finishes to choose from, Qingchang gives you the freedom to create the perfect look.

China Professional Lamp Shade Harps Supplier & Manufacturer

Lamp Shade Harps mount below the lamp socket “saddle” and holds up your lamp shade. Most harps are detachable, made up of a bottom wing piece and top harp-shaped height piece.Qingchang Industrial has a large variety of Lamp Shade Harps in many styles, shapes, and finishes. We has crafted a product line of Lamp Shade Harps in order to provide quality and pleasure.

We specialize in providing Lamp Harps that are not only durable but also beautiful.

Our Lamp Harps are made from metal materials. They are designed to hold your lampshade securely in place, making sure it stays in place at all times.

We offer a wide range of lamp harps for a variety of lamp designs.

We offer wholesale and custom service, which means you can order our Lamp Harps in bulk at affordable prices.

Our Lamp Harps are popular with customers from different parts of the world, including Europe and North America.

If you are looking for a reliable Lamp Harps supplier, look no further than Qingchang. Contact us today and enjoy our exemplary service.

General

| Material: | Metal |

| MOQ: | 100pcs |

| Lead Time: | 1-7 days for stock goods; 7-19 days for bulk production |

| Packaging Details: | PE bag / customized requirements |

| Customized packaging: | Min. order: 1000 |

| Supply Ability: | 100000 Piece/Pieces per Month |

| Business Type: | Manufacturer, Exporter |

Types of Lamp Harps

We have a huge selection of lamp harp sizes, from 4 inches to 12 inches tall. So you’re sure to find the right size to match your fixture.

Our lamp harps are made with heavy-duty metals to prevent bending or warping, and the finish is designed to resist tarnishing. In other words, our harps will last as long as your lamp! Take a look below and find the perfect lamp harp for your lamp!

Lamp Harp Size Chart

Increase the appeal and marketability of your products with diverse custom lamp harp sizes. We facilitate manufacturing lamp harp sizes in different sizes, ranging from small to large and everything in between.

| 6 inch lamp harp |

| 6.5 inch lamp harp |

| 7 inch lamp harp |

| 7.5 inch lamp harp |

| 8 inch lamp harp |

| 8.5 inch lamp harp |

| 9 inch lamp harp |

| 9.5 inch lamp harp |

| 10 inch lamp harp |

| 10.5 inch lamp harp |

| 11 inch lamp harp |

| 11.5 inch lamp harp |

| 12 inch lamp harp |

| 14 inch lamp harp |

Couldn’t find what you looking for?

Generally, there are stocks of common lamp finials or raw materials in our warehouse. But if you have special demand, we also provide customization service. We also accept OEM/ODM.

Why Choose Us?

We have consistently embraced innovation to provide full and specific lamp shade harps, ceiling fan pull chain,lamp finials and lighting accessories solutions for our every valuable customers.

One Stop Supply:

A full range of lighting accessories supply. The biggest and largest lamp shade accessorie and shades supply in China.

Reliable & Stable:

More than 30 years to work with more than 1000 old customers around the world. We have stable supply chain to support our customers at reasonable price and stable quality.

Outstanding service and On time Delivery

Any way of transports is available. The best of Mini Order support for our clients. The largest stock to support the request of on time delivery.

Lamp Harps - FAQ

The Difference Between a Heavy Duty Lamp Harp and a Light Duty Lamp Harp is the Thickness of the Metal Wire it is Made From. Since the Wire is Thicker the Harp Bottom (Saddle) must have Larger Openings to Accommodate the Larger Wire.

Heavy Duty Lamp Harp Approx. O.D. = 0.195"

Light Duty Lamp Harp Approx. O.D. = 0.18"

1/4-27 Male

The Top of a Standard Style Lamp Harp is 1/4-27 Male. A Matching 1/4-27 Female Finial Should be Used to Hold the Lamp Shade to the Harp. You can find 1/4-27 threaded finials Here!

The harp holds the lamp shade to the lamp, and is removable. If you can see an inch of lamp hardware below the shade, you may need to get a harp that is 1″ shorter. If your lamp shade hangs down too low and is covering up your lamp base, you need to get a taller harp that will raise the shade the appropriate amount.

Adjustable Harp

Boudoir Harp

Cup Harp

Handel Style Harp

Heavy Weight

Heavy Weight Harp Base

Harps are available in either regular or heavy duty weights.

Regular harps, which are available with either nickel or brass-plating, range in size from 4” to 15”.

Heavy duty harps, which are also available in nickel and brass plating, come in sizes from 5.5” and 15”.

Qingchang’s Lamp Harp Customization Capabilities

Unique Lamp Harps, Custom Wholesale Supplier

Do you need a reliable supplier of custom lamp harps in various sizes and finishes?

Just look at Qingchang. With over 20 years of experience, we specialize in making hardware lamp harps that are durable and stylish. Our harps are available in a variety of colors including black, white, silver, gold and bronze. We also provide custom finishes upon request to meet your specific needs.

Contact us today and let us help you find the perfect lamp harp for your project.

FAQ For Lamp Harps

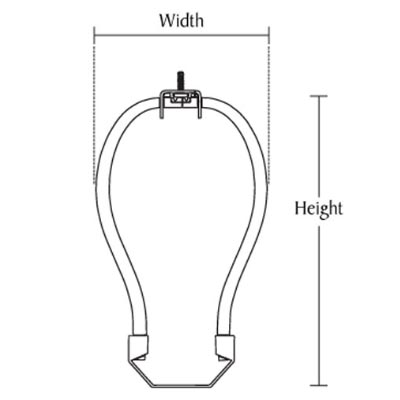

The size of lamp harp usually includes two aspects of height and width. Height is usually measured from the bottom to the top of the socket. Width refers to the lateral distance of the lamp harp.

In general, the height of the lamp harp should be at least half the height of the lampshade, with the top of the lampshade aligned with the top of the lamp socket. Usually the height of the lamp harp is given in the range of 6-12 inches, and the width is determined according to the specific lampshade and lamp holder design.

It should be noted that the size of the lamp harp should match the lamp socket used to ensure that it can firmly hold the lampshade and provide sufficient support and stability. When purchasing a lamp harp, it is best to confirm the size and type of the lamp holder first, and then choose the appropriate lamp harp.

Metal light strings are usually made of metal materials such as iron, aluminum, copper, etc., which can provide sufficient strength and durability, and can also be coated or plated as needed to increase corrosion resistance or change color. Some metal lanterns are also designed with intricate textures or decorations to provide a more intuitive appearance.

In terms of color, metal lamp harps usually use basic colors such as silver, gold, and black to match the lamp holder and lampshade.

In addition, there are some specially designed metal lamp harps, such as graffiti-style black metal lamp harps, or colored metal lamp harps based on different theme colors, which can be selected according to personal preferences and decoration needs.

In short, to choose a suitable metal light piano, you need to consider the matching of its color and material, as well as the coordination with the theme of the entire room decoration.

To determine whether a lamp harp is compatible with a lampholder, the following factors need to be considered:

1. Lamp holder type: The lamp holder types usually include E12, E14, E26 and E27, among which E26/E27 is the most common. Therefore, looking at the lamp holder type can determine the size of the lamp harp that needs to be equipped.

2. Size of the lamp holder: To determine the size of the lamp holder, it is necessary to measure the diameter and length of the lamp holder. Measure the diameter at the base of the light socket, usually 3/8" or 1/2". Measure the length at the top of the lamp base so that the lamp harp will be placed at the correct height (usually between 8" and 12").

3. Weight limit: To determine the weight of the lampshade that the lamp harp needs to support, it is usually necessary to refer to the weight limit of the lamp holder. Generally speaking, the weight limit of the lamp holder should be twice the upper limit of the weight supported by the lamp harp.

4.Pull chain type: Choose the appropriate lamp harp according to the different pull chain types of the lamp holder. There are usually two types of rotating type and sliding type. The rotating type needs to insert the lamp harp into the lamp holder and rotate it, and the sliding type needs to insert the lamp harp into the zipper socket and fix it.

In summary, to ensure that the lamp harp is compatible with the lamp holder, it is necessary to determine the lamp holder type, size, weight limit and zipper type to ensure that the lamp harp can be inserted firmly and support the lamp shade.

Determining the quality and durability of a lamp harp requires consideration of the following:

1. Material: lamp harp can be made of different materials such as metal, plastic and wood. Metal lamp harps are generally longer lasting and less prone to rust and rot. Plastic lamp harps are usually lighter and less expensive. The lamp harp made of wood is more distinctive in appearance.

2. Thickness: The thickness of the lamp harp directly affects its durability. If the lamp harp is too thin, it is easy to bend or break. Therefore, choosing a thicker lamp harp can ensure the durability of the product.

3. Workmanship: The workmanship of lamp harp also determines its quality and durability. Good workmanship can make the lamp harp stronger and firmer. Therefore, it is recommended to choose a lamp harp with fine workmanship and reliable quality.

4. Manufacturer's brand: Choose a lamp harp produced by a brand with a good reputation and reputation to get better quality assurance.

To sum up, to identify the quality and durability of lamp harp, it can be judged by factors such as material, thickness, process, and brand. Choosing lamp harp with thicker, fine workmanship and reputable brand can increase the service life and stability of the product.

Lamp harp generally needs to pass the following international quality management certification:

1. ISO 9001 certification: This is the most influential quality management system certification in the world. Its purpose is to ensure that products and services meet the needs and expectations of customers and make continuous improvements.

2. RoHS certification: This is the European Union's requirements for the restriction of the use of hazardous substances in electrical and electronic products, and certification to ensure that the product does not contain banned substances.

3. CE certification: This is the safety standard of the European market, which involves all aspects of product design, manufacturing, packaging and use, to ensure that the product is safe and reliable.

4. UL certification: This is a safety standard for the North American market. It covers electrical, gas, and mechanical safety aspects of the product to ensure that the product meets North American safety standards.

The above certifications are the most common international quality management certifications. When purchasing lamp harp, you can check whether the product has these certifications. These certifications can guarantee product quality and safety, and are reliable symbols for consumers when purchasing goods.

When testing lamp harp samples, you can refer to the following aspects:

1. Appearance inspection: Check whether the surface of the lamp harp has obvious deformation, defect or blemish, such as oxidation, scratches, etc. At the same time, it is also necessary to check whether the surface is flat and whether there is any looseness or deformation.

2. Functional test: Test whether the lamp harp can be normally connected to the lamp and can support the lampshade. If necessary, test with a lamp to see if the lamp harp can bear the weight of the lampshade and is stable.

3. Material testing: check whether the materials used in the lamp harp meet the national and regional safety standards and quality requirements.

4. Durability test: Carry out the durability test of lamp harp to test its service life and fatigue resistance. Testing can be done with test equipment or by mock testing.

5. Quality control: You can refer to the manufacturer's quality control standards, such as ISO 9001, etc., as well as the manufacturer's quality inspection report. At the same time, the quality guarantee of the product can be determined according to the quality guarantee period of the product.

To sum up, when performing lamp harp sample testing, it is necessary to conduct tests in terms of appearance inspection, functional testing, material testing, durability testing, quality control, etc., to ensure that the product quality meets the requirements.

In the production process, the CNC machining process is generally adopted, and the metal materials are processed by cutting, bending, stamping, drilling and other processing operations through the automatic control system. These operations can effectively improve production efficiency and product quality.

The main process steps of metal lamp harp production are as follows:

1. Material selection: According to customer needs, select metal materials that meet the requirements to ensure product performance and appearance.

2. Design: Design according to user needs or product standards, including various size parameters, hole effects and surface treatment requirements.

3. Cutting: Use a cutting machine to cut the metal plate to determine the qualified lamp harp size and shape.

4. Bending: Use a bending machine to bend the metal plate, and bend the metal plate into the desired shape to achieve various functions.

5. Stamping: Use a stamping machine to mold the metal mold into the required holes to realize the functions of the lamp harp, such as supporting the lampshade and carrying the lamp holder.

6. Surface treatment: Surface treatment of lamp harp by roughening, electroplating, painting, etc., to protect and beautify the product.

7. Quality inspection: Carry out quality inspection for each sample to check whether the product meets customer needs and strict inspection standards.

To sum up, in the production process of metal lamp harp, a variety of advanced technologies and strict quality inspection and control are required to ensure product quality and the realization of customer needs.

The material of the metal lamp harp generally includes metal materials such as aluminum alloy, stainless steel and copper.

1. Aluminum alloy: Aluminum alloy is light, strong and corrosion-resistant, which is more suitable for making lighting accessories. In addition, aluminum alloy also has good thermal conductivity, which can quickly and effectively dissipate lamp heat to protect lamps and electrical components.

2. Stainless steel: Stainless steel metal is very corrosion-resistant, has high strength and long life, and is also very easy to clean and maintain. Stainless steel lamp harp is suitable for high-end lamps, with high-grade texture and appearance.

3. Copper: Copper metal is soft and easy to process into various shapes. Moreover, copper metal also has good electrical and thermal conductivity, which can protect lamps more effectively and prolong their service life. In addition, the color and texture of copper are very beautiful, and it is more suitable for making various European or classical style lamps.

Generally speaking, the material selection of metal lamp harp is different according to the style, style, use occasion, demand, etc. of the lamp. Each material has its own advantages and disadvantages, and it is necessary to choose the appropriate material to manufacture lamp harp according to the actual situation.